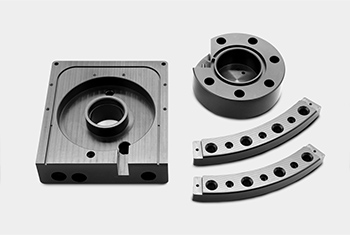

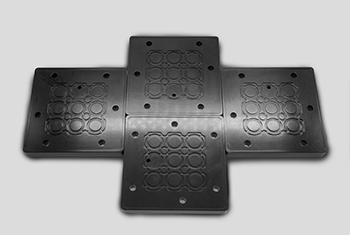

Precision CNC Machining

- CNC Milling, Turning, Wire Erosion, Sinker EDM

- MUD System with Low Tooling Cost

- Tight Tolerance to ±0.01mm

- 1 to 500+ Parts in Plastic and Metal

We combine the latest CNC machining and turning processes with proprietary technology to deliver high quality, on-demand parts. Our typical tolerance accuracy ranges from +/-0.001″ to 0.005″, depending on customer specs.

We combine the latest CNC machining and turning processes with proprietary technology to deliver high quality, on-demand parts. Our typical tolerance accuracy ranges from +/-0.001″ to 0.005″, depending on customer specs.

Five-axis machining is the use of CNC to move parts or cutting tools on five different axes

simultaneously, which can process very complex parts.

Five-axis machining is the use of CNC to move parts or cutting tools on five different axes

simultaneously, which can process very complex parts.