We are a custom injection molding manufacturer that makes parts your way in 7-15 days or less. We have advanced manufacturing facilities, provide an unlimited lifetime mold guarantee, can produce parts from many engineered grade resins.

At WeLead Rapid,we are together to perfect our customers’ part without starting to make the part straight away. Rough DFM provided during quoting stage, so that customer will get deeply understand the parts at a production view. At the beginning,

engineering suggestions will be put forward, such as undercuts, wall thickness, sink marks, strength to adjust before production.

After order placed, detail DFM will be provided to confirm draft angle, injection gate, ejection pin area, radii, assembly issue etc.We will make sure you get exactly what you expect.

We are a custom injection molding manufacturer that makes parts your way in 7-15 days or less. We have advanced manufacturing facilities, provide an unlimited lifetime mold guarantee, can produce parts from many engineered grade resins.

At WeLead Rapid,we are together to perfect our customers’ part without starting to make the part straight away. Rough DFM provided during quoting stage, so that customer will get deeply understand the parts at a production view. At the beginning,

engineering suggestions will be put forward, such as undercuts, wall thickness, sink marks, strength to adjust before production.

After order placed, detail DFM will be provided to confirm draft angle, injection gate, ejection pin area, radii, assembly issue etc.We will make sure you get exactly what you expect.

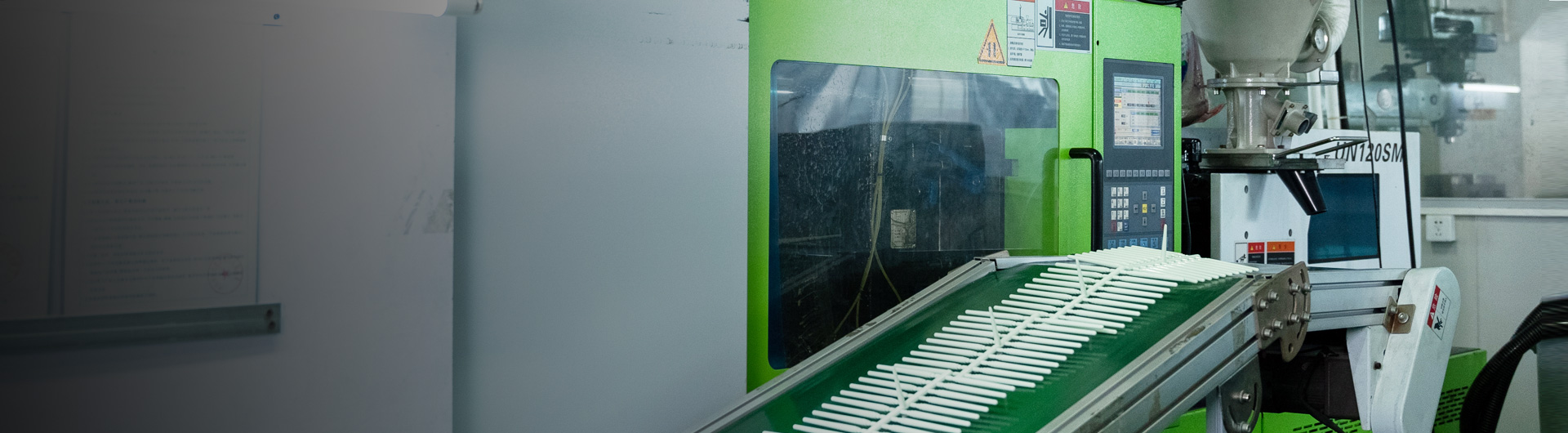

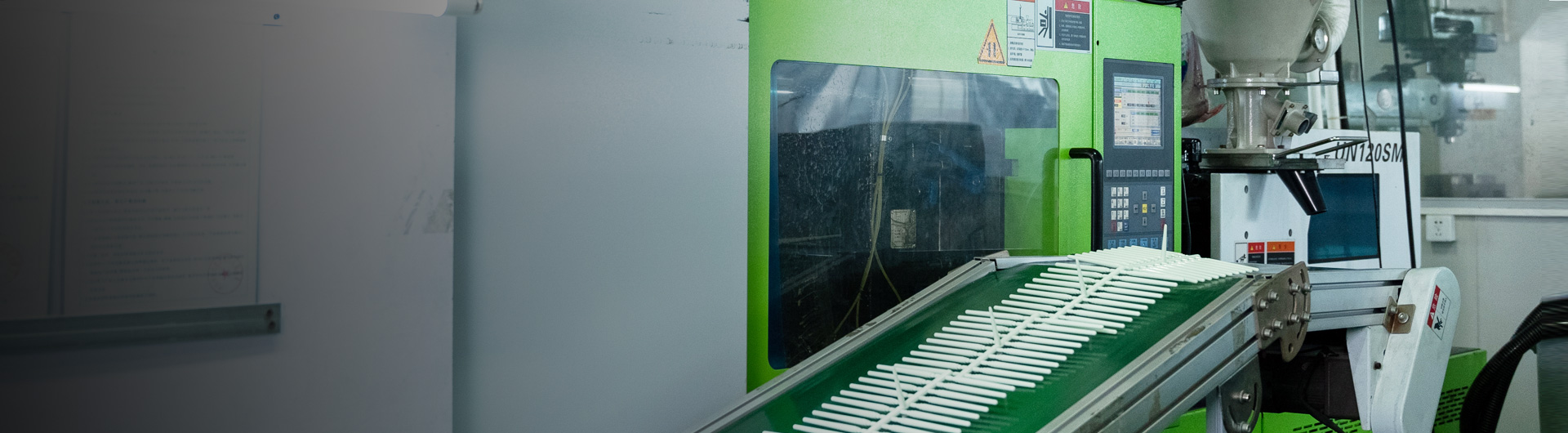

Injection Molding Process

Injection Molding includes 4 steps, clamping, injecting, cooling, ejecting. These 4 steps are very critical for molding all the products into right shape and high quality. Our experienced and skillful workers are professionalized in optimizing the parameters and experience in all kinds of unexpected factors. T1 sample will be sent to customers within lead time as estimated in our quotation. We will fix the mold until customer confirm it.

We are a custom injection molding manufacturer that makes parts your way in 7-15 days or less. We have advanced manufacturing facilities, provide an unlimited lifetime mold guarantee, can produce parts from many engineered grade resins.

We are a custom injection molding manufacturer that makes parts your way in 7-15 days or less. We have advanced manufacturing facilities, provide an unlimited lifetime mold guarantee, can produce parts from many engineered grade resins.